PENGARUH METALLIC CATALYTIC CONVERTER TEMBAGA BERLAPIS CHROME DALAM MENURUNKAN EMISI GAS BUANG MESIN SEPEDA MOTOR EMPAT LANGKAH

Sudirman Rizki Ariyanto(1), Retno Wulandari(2), Suprayitno Suprayitno(3*), Pramuko Ilmu Purboputro(4)(1) Universitas Negeri Malang

(2) Universitas Negeri Malang

(3) Universitas Negeri Malang

(4) Universitas Muhammadiyah Surakarta

(*) Corresponding Author

Abstract

Keywords

Full Text:

PDF (Bahasa Indonesia)References

K. Khivantsev et al., “Palladium/Zeolite Low Temperature Passive NOx Adsorbers (PNA): Structure-Adsorption Property Relationships for Hydrothermally Aged PNA Materials,” Emiss. Control Sci. Technol., vol. 6, no. 2, pp. 126–138, Jun. 2020, doi: 10.1007/s40825-019-00139-w.

Warju, “Pengaruh Penggunaan Catalytic Converter Tembaga Berlapis Mangan Terhadap Kadar Polutan Gas Buang Motor Bensin Empat Langkah,” Institut Teknologi Sepuluh Nopember Surabaya, 2006.

R. M. Bagus Irawan, P. Purwanto, and H. Hadiyanto, “Optimum Design of Manganese-coated Copper Catalytic Converter to Reduce Carbon Monoxide Emissions on Gasoline Motor,” Procedia Environ. Sci., vol. 23, pp. 86–92, 2015, doi: 10.1016/j.proenv.2015.01.013.

S. Dey and G. Chandra Dhal, “Controlling carbon monoxide emissions from automobile vehicle exhaust using copper oxide catalysts in a catalytic converter,” Mater. Today Chem., vol. 17, p. 100282, Sep. 2020, doi: 10.1016/j.mtchem.2020.100282.

I. A. N. Shoffan, S. Sumarli, and I. M. Nauri, “The effect of copper-based catalytic converter with circular tube shape on exhaust emission of Yamaha Vixion 1PA,” IOP Conf. Ser. Mater. Sci. Eng., vol. 669, p. 012014, Nov. 2019, doi: 10.1088/1757-899X/669/1/012014.

R. S. Hidayatullah, I. W. Susila, I. M. Arsana, Warju, and S. R. Ariyanto, “The Effectiveness of Using Variations in Fuel Against Engine Performance 4 Steps 100 CC with Compression Ratio 8:1,” IOP Conf. Ser. Mater. Sci. Eng., vol. 1125, no. 1, p. 012120, May 2021, doi: 10.1088/1757-899X/1125/1/012120.

SNI 09-7118.2-2005, Exhaust gas emissions - Moving sources - Part 2: How to test motorized M, N, and O category vehicles with compression-ignition engine under free acceleration conditions. Indonesia: National Standardization Agency (NSA).

Minister of Environment of the Republic of Indonesia, Regulation of the Minister of Environment of the Republic of Indonesia Number 05 of 2006 concerning the Threshold of Old Motor Vehicle Exhaust Emissions. Indonesia, 2006.

Warju, S. P. Harto, and Soenarto, “The Performance of Chrome-Coated Copper as Metallic Catalytic Converter to Reduce Exhaust Gas Emissions from Spark-Ignition Engine,” IOP Conf. Ser. Mater. Sci. Eng., vol. 288, no. 1, p. 012151, Jan. 2018, doi: 10.1088/1757-899X/288/1/012151.

R. N. Brady, “Internal Combustion (Gasoline and Diesel) Engines,” in Reference Module in Earth Systems and Environmental Sciences, Elsevier, 2013.

D. A. Vallero, “Thermal reactions,” in Air Pollution Calculations, Elsevier, 2019, pp. 207–218.

M. R. Saxena, R. K. Maurya, and P. Mishra, “Assessment of performance, combustion and emissions characteristics of methanol-diesel dual-fuel compression ignition engine: A review,” J. Traffic Transp. Eng. (English Ed., vol. 8, no. 5, pp. 638–680, Oct. 2021, doi: 10.1016/j.jtte.2021.02.003.

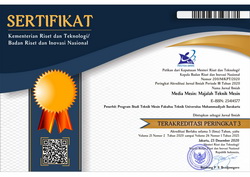

I. Prasetyo, S. Sarjito, and M. Effendy, “Analisa Performa Mesin dan Kadar Emisi Gas Buang Kendaraan Bermotor dengan Memanfaatkan Bioetanol dari Bahan Baku Singkong sebagai Bahan Bakar Alternatif Campuran Pertalite,” Media Mesin Maj. Tek. Mesin, vol. 19, no. 2, pp. 43–54, Jan. 2019, doi: 10.23917/mesin.v19i2.5698.

G. Kyriakakis, “Extraction of Gold from Platinum Group Metal Ores,” in Gold Ore Processing, Elsevier, 2016, pp. 857–870.

Article Metrics

Abstract view(s): 951 time(s)PDF (Bahasa Indonesia): 944 time(s)

Refbacks

- There are currently no refbacks.